Obstacles to storing emissions underground (Part 2)

Why does it usually take a decade or more to develop a storage site? What should companies and countries do about it?

You’re reading Terraform Now, my newsletter on the business of climate tech. Feel free to share with interested folks. You can subscribe here:

This is part 2 in our series on carbon dioxide storage. Here’s Part 1, an overview of why geologic storage matters & what formations are best for storing CO2

TLDR, geologic storage projects share a few challenges:

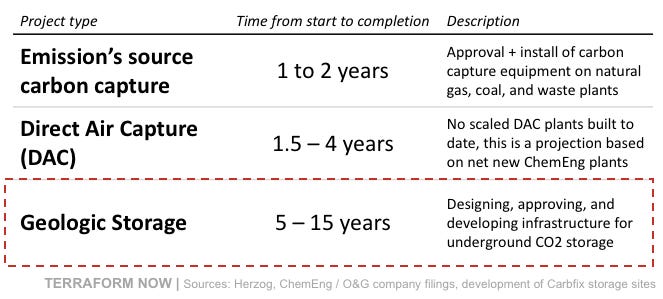

Timing: it takes longer to develop a storage site than to build a carbon capture plant

Engineering: creating a system that reliably holds CO2 underground is straightforward, but geology talent is scarce

Regulatory oversight: bureaucracies where carbon capture is taking off are slow to approve geologic storage

Safety: storing CO2 underground can increase the chance of earthquakes, though the risk appears to be low

It takes a long time to develop an underground storage site — up to 10x longer than developing a DAC plant:

It is often assumed that if/when we adopt more of a ‘wartime mentality’ with respect to climate, we’ll develop storage sites much faster. This was my assumption going into reading up on storage, but now I’m skeptical. Geological work just takes much longer than processes that most of us are more familiar with, like manufacturing. Urgency is unlikely to speed things up dramatically, and this is not a case of ‘regulators just need to get out of the way’ — though faster responses from regulators will help storage move faster, as we’ll see.

The closest analogy for doing CO2 storage (at scale) is drilling for oil, as they both involve exploring and developing caverns deep underground. During the biggest war of the 20th century, WWII, America desperately needed more oil but couldn’t bring supply up faster than 4% per year. It never grew faster than 10% in any given year. Compare oil output to another American wartime priority — making the boats that supplied English, Soviet, and American armed forces — and you can see just how much faster manufacturing scales than geological work:

You might look at this and say ‘yes but we just shifted manufacturing capacity around during the war because manufacturing boats is similar to manufacturing cars.’ But that’s exactly the point. There’s a lot of transferable skills between different types of manufacturing. Geology is different — everything is specific, from actual geologists to people who can write documents for EPA approval to specialized drill bits. Few skills transfer from other domains.

So the path to developing a lot of storage is likely to be a long, slow increase rather than a sudden leap. That said, there are a few things we can do to ensure that we develop enough enough storage:

Start now: The good news is that there are a lot of people trying to get storage sites approved, and recent demand for high-quality carbon offsets is strengthening their appeals

Pick big sites1: We should be looking for sites that are 2-3 orders of magnitude larger than current DAC plants

Pick well understood sites: Old oil and gas wells will be well documented, and their might even be living geologists and regulators who worked on them

Accelerate regulatory approval

Recruit geologists

Timing may not feel urgent now since DAC and carbon capture generally is so small. But imagine that carbon capture capacity — a manufacturing process like building boats — begins to grow at rates of 50 - 100% per year. If storage grows at only 5% a year, we could end up with storage as the scarce resource. This would be all the more frustrating given the vast amount of geologic storage available and the lack of alternatives for storing billions of tons of CO2.

Engineering talent

The actual engineering of caverns for CO2 is well understood. You need a minimum depth of ~800m, a sealing caprock, a cavern that immobilizes CO2, and assurance that there are no holes going to the surface that would allow CO2 to leak out.

Researchers have developed sophisticated models for underground storage, like this one from Nature, which focuses on sources of leakage and ways to immobilize CO2:

The engineering is not that hard, but it does require a specific type of geological skill set to do it right, and there aren’t that many people who can do the work. Most qualified geologists work at large oil & gas companies doing (lucrative) exploration and development.

I’ve written before about how many oil & gas folks will inevitably migrate to working on CO2 removal. I discussed three different skill sets from oil & gas that translate well:

Industrial construction workers for the basic infrastructure to get the plants operational

Chemical engineers to manage and improve DAC processes

Geologists to explore, develop and monitor storage sites

Of these three, geologists are the highest paid and tend to be highly specialized. That means they are hard to pry away from their companies. And while it’s all very nice to suggest that geologists take a pay cut to do more meaningful work, that’s a hard sell for an actual human trying to support their family.

We can hope that a new generation of geologists who have been focusing on CO2 storage from their university days will enter the market solve the talent shortage problem. But that is at best a long-term shift, and in the next decade recruiting great geologists will probably be a challenge for firms focused on storing emissions.

Yes, regulation is a problem

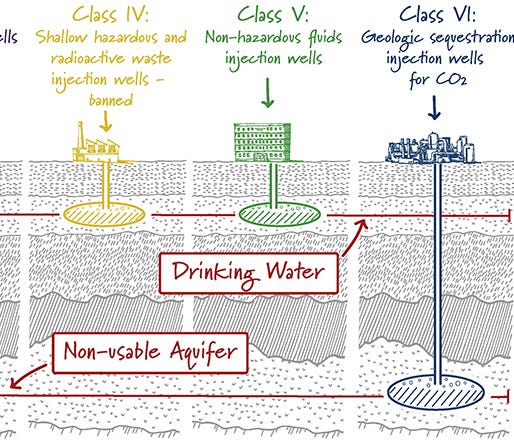

One of the things that geologists do is develop applications for regulators to approve. In the America, regulators at the Environmental Protection Agency (EPA) need to approve something called a Class VI well:

Right now there are >100 Class VI wells waiting for EPA approval, with an average wait time of around 6 years. I mentioned earlier that developing a storage site takes between 5-15 years, which means that waiting for regulatory approval is often more than half the total timeline for developing a storage site.

I’m certain that regulators have a lot of work to make sure these wells are safe and will not leak. This work involves a lot of planning, paperwork, site visits, and quadruple-checking the engineering has zero defects. I don’t mean to suggest that these are simple and easy. But the EPA should be able to move faster. In six years a single person can finish a PhD. A full team of regulators should be able to assess the risks of a project and sign off in half that time.

There’s plenty of evidence to suggest the American EPA us capable of moving faster. American fossil fuel companies discovered a bunch of natural gas in the 1930s, a time when the economy was relatively energy-poor and unemployment was at >20%. Politicians wanted to put people to work developing natural gas infrastructure, but the permitting regime was slow. So Congress wrote a law that capped the wait time for new pipeline permits at 3 years. For ~85 years, this has worked just fine. Nothing accelerates timelines like a deadline.

Politicians in America and the EU say they are concerned about climate change, and have doled out hundreds of billions of dollars for all things green. But the critical path for most climate tech — from renewables to storage — is painfully slow permitting.

Two groups are unintentionally holding up permitting reform. Environmentalists worry that it will accelerate fossil fuel projects, and they’re correct. Some right-leaning folks argue that if solar and wind are cheaper than fossil fuels, they’ll win on the open market. This is mostly2 correct, but muddied by other right-leaning folks who are champions of fossil fuels because their local economy depends on them or for national security reasons. Every time Congress gets close to permitting reform, one of these groups throws a wrench in the negotiations that angers another group, and all agree to scrap the whole thing.

To the EPA’s credit, they are making strides toward making permitting more transparent, but this is a far cry from the acceleration that carbon capture needs.

Preventing earthquakes

Even if regulators should move faster, I’m not arguing for deregulation. The EPA and other regulatory bodies should be closely involved managing the risks of geologic storage. Pumping lots of liquid (like CO2) underground tends to change the pressure in underground caverns, and this can cause earthquakes. The good news is that the industry and regulators both have very recent experience with this exact problem.

From 2008, America experienced a boom in oil production as a result a somewhat destructive process called fracking. Around this time, there was a large increase in earthquakes, especially in Oklahoma:

In the popular imagination these shakes were a result of fracking, but that’s a myth. It was the result of what oil & gas companies call ‘wastewater management.’ As I covered in our earlier post on geologic storage, oil is often mixed with water that is briny and gross to the point of being poisonous. When companies drill for oil, a bunch of this water comes shooting out of the well, and because it’s so dangerous it has to be sent back down quickly or dealt with very carefully and at great expense. Oil companies started pumping this wastewater right back underground at very high pressures. This caused the massive spike in earthquakes in Oklahoma and other states.

If you put the massive spike in man-made Oklahoma earthquakes in the context of what happens naturally in California, the wastewater scandal does not seem like a big deal:

I’m not saying earthquakes are good, but they are manageable. I’ve lived in California for about half my life, and have been near the top floor of San Francisco’s tallest building during 4.0 earthquake. It was a little unsettling, but Californians have been making buildings with earthquake-proof designs for over a century, so I was fine. I’m more worried about a tree falling on my house in a storm than the next big shake.

The good news is that in recent years, oil companies and the EPA have worked hand-in-hand to drastically reduce the number of earthquakes, and better practices will continue to bring these down. Lessons learned about how not to over-pressurize can be applied directly to CO2 storage.

Final thoughts on balancing risk

This article has spent a lot of time focused on the good and the bad of the American EPA. In part that’s because I just understand it better, being an American. But it’s also because folks thinking about storage have the most to learn from the EPA’s recent history.

America has a larger appetite for geologic risk than most other conscious countries. America’s quest for energy independence in the mid-2000s kicked off many new oil and gas projects, which gave geologists and onsite engineers real-world training. And, importantly, successive American presidential administrations were willing to take environmental risks with fracking. The ‘move fast and break things mentality’ taught both regulators and companies how to responsibly deal with risky new technologies.

While most environmentalists might hate to admit the irony here, this experience is already doing wonders for geologic storage. The technology for storing CO2 underground is child’s play relative to sophisticated fracking techniques. As a result, America is set to be the leader in geologic storage in the next few years, in large part on the back of its deep skill set and a relatively permissive regulatory regime. I’ve criticized the EPA plenty in this article, but at least they are approving Class VI wells.

That’s more than you can say for Germany, the EU’s biggest economy. It too has deep reserves of natural gas, but did not invest in energy independence in the last few decades. The short-term consequences of this decision are high energy prices, a direct result of relying on Russia for a key resource. Then there are the longer-term consequences for Germany’s chances of doing geologic storage of CO2:

The public is scared of geologic work

The regulatory regime is not staffed with many geologists who can make calls on what storage projects are safe

The actual geology of Germany is not all that well documented, at least relative to the entirely mapped Gulf Coast of the US

As a result, Germany is not building geologic storage with any urgency, hoping instead to store CO2 ‘cooperatively’ in the North Sea — this is code for paying a consortium of Norwegian and British entities to store CO2 somewhere else. I’m not saying that this won’t work out for Germany, but they have much less control over their carbon management supply chain than America, and as a result have less room for real ambition. This is likely to show in the data in the coming years.

A part of me understands why Germany takes this stance. The idea that you might create earthquakes by putting emissions underground is unsettling. It’s a more dense country than the US, so (potential) shakes are more likely to affect people. But, as we’ve seen, these shakes can be eliminated or managed.

Rich, climate conscious countries like Germany should balance the risk of shakes with the good that storing emissions could do. Earthquakes are a local problem that can be controlled by a good regulatory state and a responsible construction sector. Climate change is obviously a big global problem — but more than that, the market for carbon offsets is fast-growing market that is rewarding good entrants with high-quality offsets. It’s better to develop local, German champions now, while demand exceeds supply, than come late to the party.

Another way to think about the timing problem is that there are massive fixed costs associated with developing a single storage site, and those fixed costs only go up a little bit if the cavern is an order of magnitude larger. These fixed costs are not strictly monetary, but an opportunity cost for everyone involved — from regulators to geologists to line engineers. Viewed from this lens — high opportunity cost per site — it makes sense to take the extra time to find the largest possible sites, spreading out opportunity costs over a larger tonnage

By some metrics, natural gas is cheaper than solar and wind, especially because it can provide power at any moment